Exhibition

Circular Economy

Innovations are making it possible to recirculate resources which previously went to waste, such as CO2.

Just as organic materials return to the earth, these innovations are breathing new life into waste products.

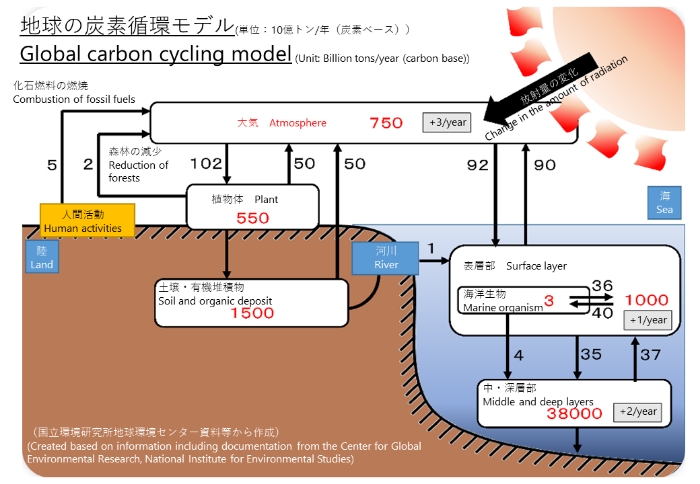

We aim to realize a carbon recycling society through the utilization of CO2 as a resource

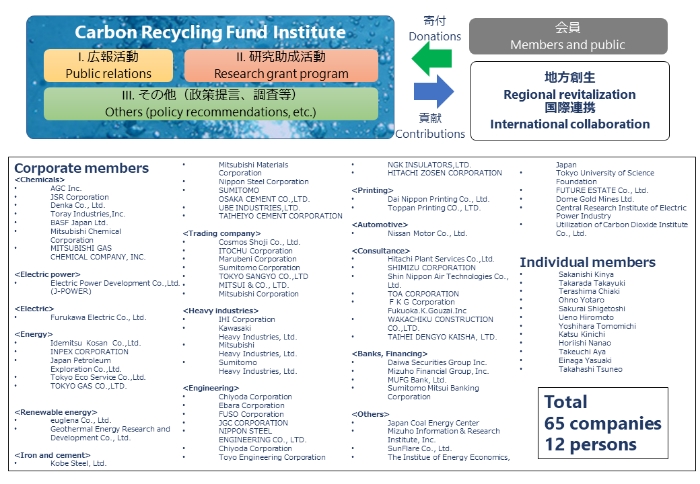

Carbon recycling is not a way of thinking about CO2 as the final form of energy production, but rather encouraging a carbon cycle by considering and utilizing CO2 as a resource. CO2 can be used in a wide range of fields such as chemistry, agriculture, forestry, fisheries, materials, and life sciences. We support the activities of various companies and individuals engaged in carbon recycling on a private basis in order to implement carbon recycling in society with the aim of simultaneously solving the global warming problem and the energy access problem. Research grant activities support basic research with excellent originality and innovation related to carbon recycling, and support for demonstration tests and social implementation, which are the next steps, by discovering hidden ideas and people in companies and universities.

Carbon Recycling Fund Institute

https://carbon-recycling-fund.jp/aboutus/en.php

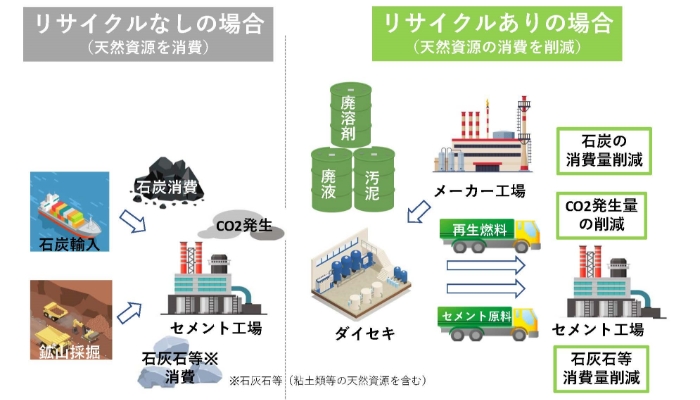

The following diagram illustrates the concept of ”reduction of greenhouse gas emissions and building a recycling-oriented society through industrial waste recycling”.

Reduction of Greenhouse Gas Emissions and Building a Recycling-Oriented-Society

“through Industrial Waste Recycling”

Recycled fuels are made from various waste solvents,and cement materials are recycled products made from sludge.In general, cement production requires a large amount of coal and limestone (including natural resources such as clay).However,by using recycled fuel and cement materials as a substitute for them, the consumption of coal and limestone can be reduced. If the waste solvents and other materials are not recycled,they are incinerated just as wastes(and generate CO2),and more CO2 is generated by incineration of coal during cement production. Therefore,the applicaition of recycled fuels for cement producion reduces CO2 generation. In this way, Daiseki is working together with cement companies to reduce greenhouse gas emissions and build a recycling-oriented society.

Daiseki Co.,Ltd.

https://www.daiseki.co.jp/english/business/recycle/index.html

From Renewable energy development to Reduce resource consumption

In order to achieve carbon neutrality by 2050, it is necessary to change the social and economic system from mass production and mass consumption to a recycling economy. The United Nations Environment Programme (UNEP) is trying to realize the transition to a recycling-oriented economy through the collaboration of all stakeholders. In August 2020, in collaboration with the United Nations Development Programme (UNDP), " A 1.5℃ world requires a circular and low carbon economy " was released. In this exhibition, Tokyo Steel Co., Ltd., which works on the recycling of metal resources from among the member companies, was taken as an example.

Ever since its founding, Tokyo Steel has continually expanded its product line from basic long steel products to higher value-added steel products.

It has been made possible to manufacture high-quality steel from iron scrap by using an electric furnace, which was previously considered to be impossible without iron ore and coal being made in a blast furnace. As a result, CO2 emissions during manufacturing can be reduced to 1/4, underground resource consumption can be significantly reduced, and they are one of companies that are working daily toward the realization of a "decarbonized society" and a "recycling-oriented society" in 2050.

Japan Association for the United Nations Environment Programme

http://www.tokyosteel.co.jp/eco/english/

Office scenery to discuss initiatives for a sustainable society

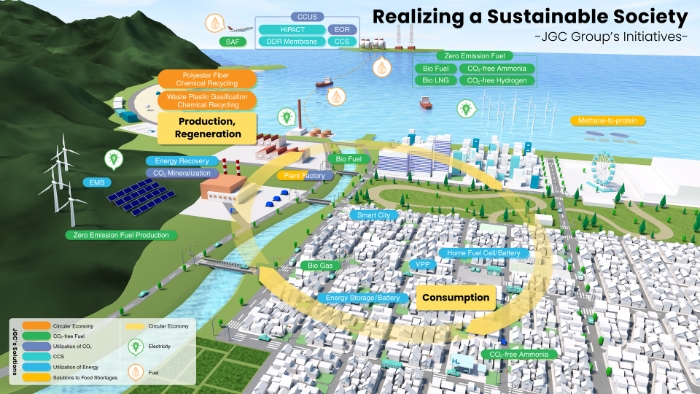

JGC Group's Initiatives

Realizing a Sustainable Society

Recognizing how firmly established the trend toward building sustainable societies has become, the JGC Group is focusing on our own environmental and other technologies, drawing on collaboration with corporations and universities that maintain and develop other advanced technologies, to promote new business. We will introduce 4 initiatives as below.

・Waste Plastic Gasification Chemical Recycling

・CO2-free Ammonia

・CO2 Separation and Recovery using a DDR-type Zeolite Membrane

・Production of Sustainable Aviation Fuel

JGC Holdings Corporation

https://www.jgc.com/en/esg-hsse/initiative/

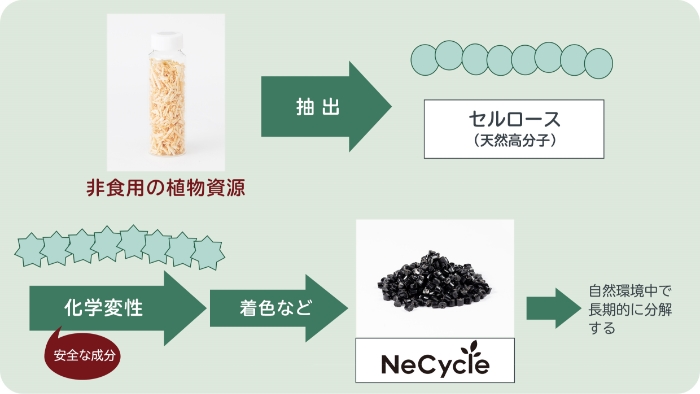

Consists of cellulose (about 50%) and safe ingredients extracted from non-edible plant resources that do not affect food problems.

It has durability that can be applied to a wide range of products, and formability that can be mass-produced by injection molding.

Highly functional bio material NeCycle

The high quality decorativeness of Japanese traditional craft lacquer ware has been realized with biomass-plastic materials. We will contribute to the realization of a low-carbon society and a resource-circulation society by expanding the application range of plastic materials based on non-edible biomass (cellulose).

<Features>

■ Approximately 50% of non-edible plant material (cellulose) is used. The remaining 50% uses safe ingredients

■ While having durability that can be applied to a wide range of products, it biodegrades in the natural

environment for a long period of time and suppresses environmental pollution at the time of outflow.

■ Realized the beauty of high-class lacquer ware (lacquer black) without painting through joint development with Yutaro Shimode, a leading lacquer artist in Japan.

NEC Platforms Ltd.

https://www.nec.com/en/global/rd/technologies/202003/index.html

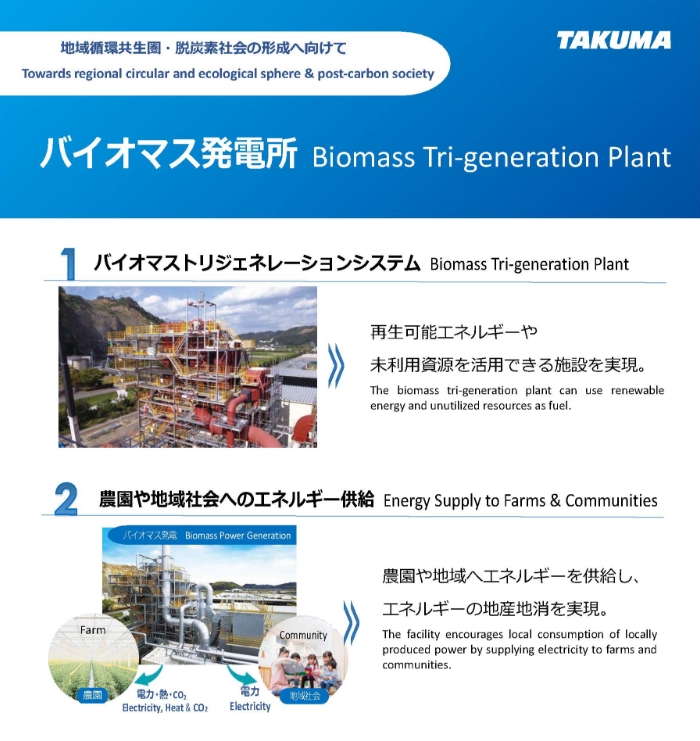

Together in the community - introducing Energy from Waste (EfW) Plant and Biomass Power Plant

The Imabari City Waste Management Center incinerates solid waste from about 160,000 residents of the city of Imabari and uses the resulting thermal energy to generate electricity. The plant is the first solid waste treatment facility in Japan to adopt the "Phase Free" concept, allowing it to function as a place where residents can gather and enjoy interaction with other members of the community during times of normal operation and as a designated evacuation center where residents can seek refuge in times of disaster.

The biomass power plant and combustion gas purification system installed in this project use lumber from nearby regions and imported wood products such as palm kernel shells (PKS) as fuel in a biomass tri-generation plant that supplies three types of energy necessary for facility operation: electricity, heat for heating and cooling use, and carbon dioxide for promoting vegetable growth. In this way, the facility can be operated in a sustainable manner.

TAKUMA CO., LTD.

https://www.takuma.co.jp/english/product/boiler/biomass/kasaoka.htmlBiomass Power Plant Construction / O&M Project in Kasaoka

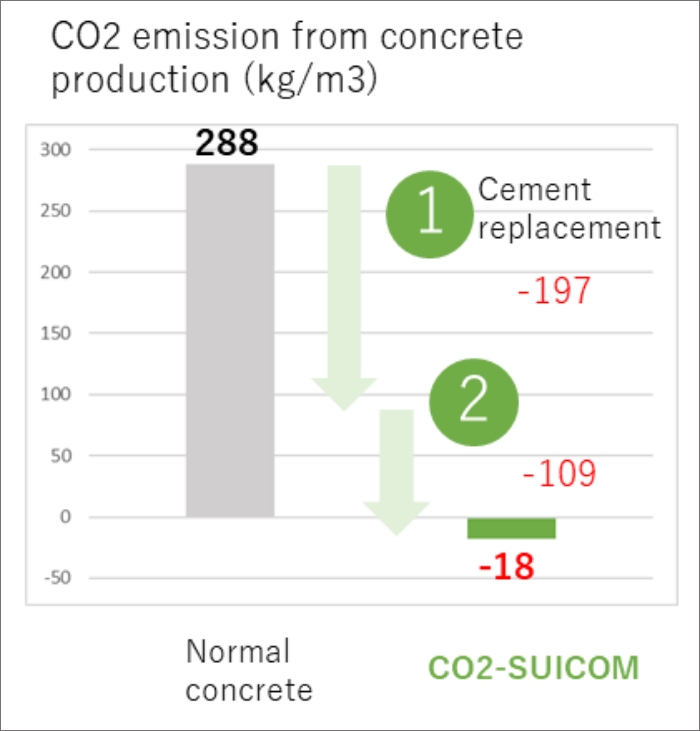

Carbon Negative Concrete "CO2-SUICOM"

CO2-SUICOM is the world's first commercialized carbon negative concrete technology.

In Japan, it is already used for construction of highways and paved roads, etc., and we are now promoting commercialization overseas. In order to decarbonize our society, The Chugoku Electric Power Company, Kajima Corporation, Denka Corporation and Landes Corporation has developed the technology, and Mitsubishi Corporation is in charge of commercialization overseas.

A CO2-SUICOM concrete block can reduce CO2 emissions equivalent to what a cedar tree can absorb in a year. This is a break thorugh technology for for concrete which is one of the most consumed materials in the world.

With the power of CO2-SUICOM we aim to realize a sustainalble society by decarbonizing the global infrastructure.

The Chugoku Electric Power Company

Kajima Corporation

Denka Corporation

Landes Corporation

Mitsubishi Corporation

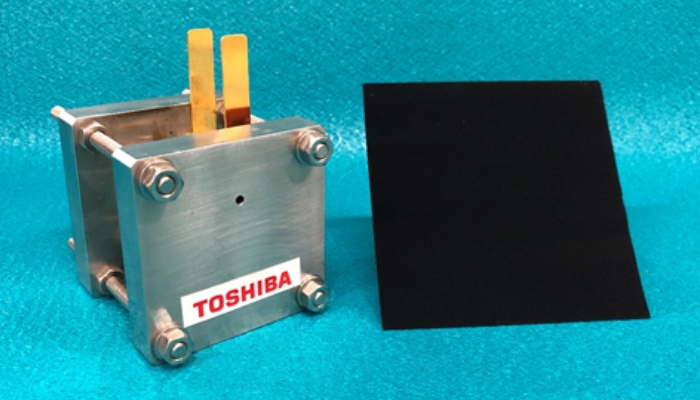

CO2 recycling cell

Developed porous cathode catalyst electrode

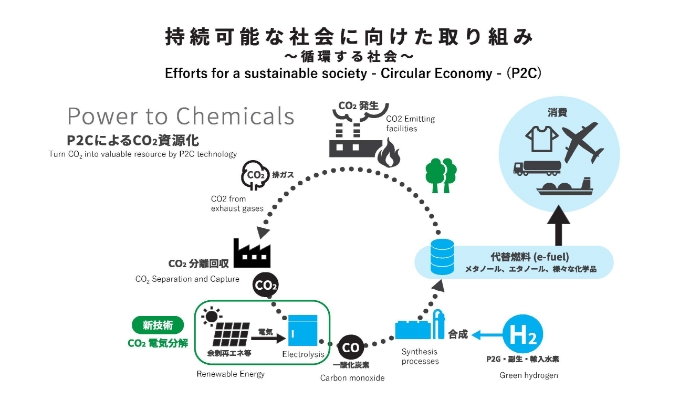

Power to Chemicals -Carbon Recycling Technology using Renewable Energy-

We have developed CO2 electrochemical cells capable of high throughput operation, based on artificial photosynthesis technology. This revolutionary technology reduces CO2 emissions from factories and other facilities, while also solving the problem of surplus power prevalent with the spread of renewable energy. By utilizing systems combining renewable/surplus power with CO2 as a resource, a decarbonized society becomes possible, and will promote innovations leading to a positive cycle in both the environment and economic growth. The technology can be shrunk to a small footprint by high throughput operation, allowing the CO2 processing to take place efficiently next to a CO2 emission facility, thus promoting local energy production and consumption fit to the needs of the locale, as well as creating opportunities for various businesses to solve local issues.

TOSHIBA CORPORATION

https://www.toshiba.co.jp/rdc/rd/detail_e/e1903_02.htmlToshiba Leads the World in Converting CO2 into Useful Materials for Chemical Products

-New Technology Reduces CO2 Emissions, Can Contribute to Achieving Paris Agreement Targets-